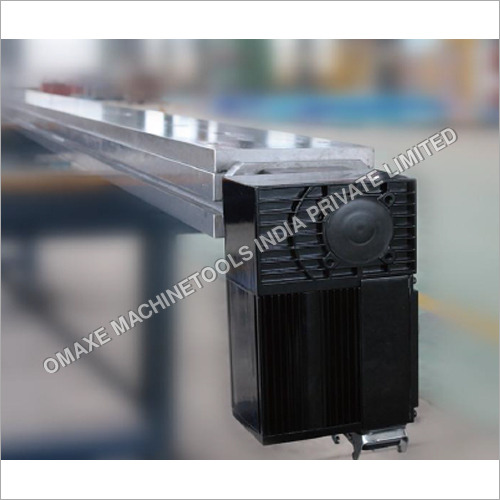

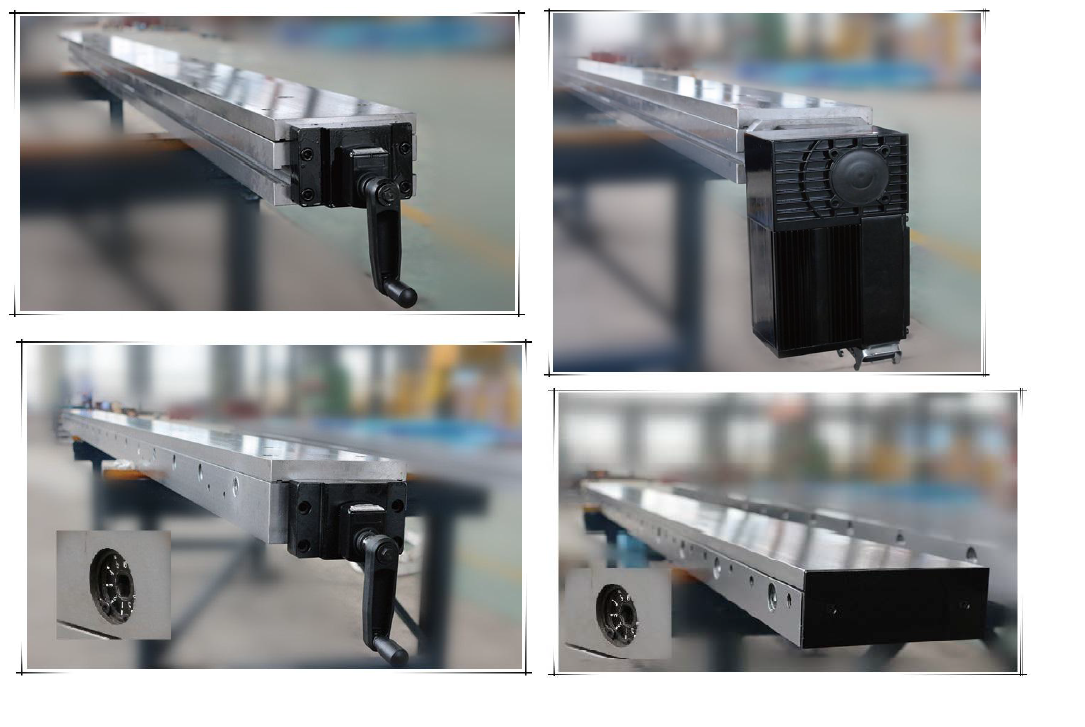

Press Brake Crowning System

120000.00 INR/Unit

Product Details:

- Usage Industrial

- Material Stainless Steel

- Size Different Sizes Available

- Product Type PRESS BRAKE CROWNING SYSTEM

- Color Silver

- Length 6 Millimeter (mm)

- Click to View more

X

Press Brake Crowning System Price And Quantity

- 120000.00 INR/Unit

- 1 Unit

Press Brake Crowning System Product Specifications

- PRESS BRAKE CROWNING SYSTEM

- Stainless Steel

- Different Sizes Available

- Industrial

- 6 Millimeter (mm)

- Silver

Press Brake Crowning System Trade Information

- AHMEDABAD

- 1 Unit Per Month

- 20-25 Days

- All India

Product Description

Most Crowning Systems are available with CNC drive motors. With CNC the press brake operator needs only to enter the pertinent programming data into the machines control, and the combination of the independent control axis and the CNC motor will automatically set the crown to the proper position prior to each bend. We also provides crowning systems with manual hand cranks that have digital readouts. These units are less expensive than the CNC controlled units and are therefore very popular with new press brake buyers and as retrofits to existing machines.

Enhance Bending Precision

The Press Brake Crowning System utilizes advanced engineering to counteract ram and bed deflection during metal bending tasks. By integrating this stainless steel crowning unit, users achieve consistent, high-quality results across different jobs, minimizing errors and material wastage.

Durable Stainless Steel Construction

Crafted from robust stainless steel, the crowning system offers superior resistance to wear, deformation, and corrosion. Its reliable silver finish further enhances protection, helping the unit withstand rigorous industrial environments for prolonged use.

Versatile Sizing and Application

Available in lengths of 6 mm and in multiple sizes, this crowning unit can be easily customized to fit a wide variety of press brake machines. Its design supports different industrial bending projects, ranging from small-scale fabrications to heavy-duty manufacturing tasks.

FAQs of Press Brake Crowning System:

Q: How does the Press Brake Crowning System improve bending accuracy in industrial applications?

A: The crowning system compensates for deflection in the press brakes ram and bed, ensuring an even distribution of force. This results in precise, uniform bends throughout the entire length of the workpiece, reducing rework and scrap.Q: What is the process for installing the crowning unit on my press brake machine?

A: Typically, the crowning unit is mounted directly onto the press brakes lower beam. Installation guidelines vary depending on the machine model, but they generally involve securing the unit and making necessary adjustments to align with your bending requirements.Q: When should I use a crowning system in my manufacturing process?

A: A crowning system should be employed when working with longer workpieces or higher-tonnage bends, as it addresses deflection issues that can compromise accuracy in these scenarios. It is especially beneficial in applications demanding repeatable results.Q: Where is the Press Brake Crowning System manufactured and supplied from?

A: This crowning unit is manufactured and supplied directly from China by an established manufacturer and supplier, ensuring reliable quality and service for international industrial markets.Q: What are the main benefits of using a stainless steel crowning unit in my press brake operation?

A: Stainless steel construction offers excellent strength, corrosion resistance, and durability, allowing the crowning unit to maintain performance even under heavy industrial use. This extends the units service life and minimizes maintenance costs.Q: Which sizes are available for this crowning system, and how do I choose the right one?

A: This unit comes in a 6 mm length, with other sizes offered to fit diverse press brake machines. Selection is based on the size and specifications of your press brake, as well as the bending tasks you routinely perform.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese